You can see them all around Bangladesh. There are hundreds of them. Some say more than 15’000. The high chimneys along the rivers and cities pouring constantly smoke into the air. Millions of bricks are burned there. But the price is high and paid by the local and from far coming workers and the environment surrounded by those factories.

You can see them all around Bangladesh. There are hundreds of them. Some say more than 15’000. The high chimneys along the rivers and cities pouring constantly smoke into the air. Millions of bricks are burned there. But the price is high and paid by the local and from far coming workers and the environment surrounded by those factories.

Bangladesh is a rapidly urbanizing country having a 163 million population. This generates a very high amount for cheap building materials and gave brickmaking a go.

But most of them are illegally built. In late 2019 excavators flanked by Bangladesh riot police are at work demolishing illegal soot-belching brick kilns around the smog-choked capital Dhaka, forcing migrant laborers out of work and back to their villages. This led to a lot of unemployed people in Bangladesh. Furthermore authorized brick kilns that are using the soil of hills and arable land for making bricks and using wood as fuel in the kilns will be reported to the court.

Bangladesh is hit harder than almost any other country in the world by climate change despite emitting very few greenhouse gases. But the emissions from the brick kilns hurt the environment. The cluster of traditional kilns have been proven to hamper air quality in the country. Local groups and the government have been working to bring clean brick kilns and sustainable technology to the works.

Brick kilns are responsible for 58% of air pollution in the capital. Plans have been taken to shut traditional kilns currently in operation all over the country. “We’re working to produce eco-friendly bricks,” said Environment, Forests, and Climate Change Minister Md Shahab Uddin lately. He said the government plans to stop burning bricks at kilns by 2025 and use block bricks to construct buildings under government projects.

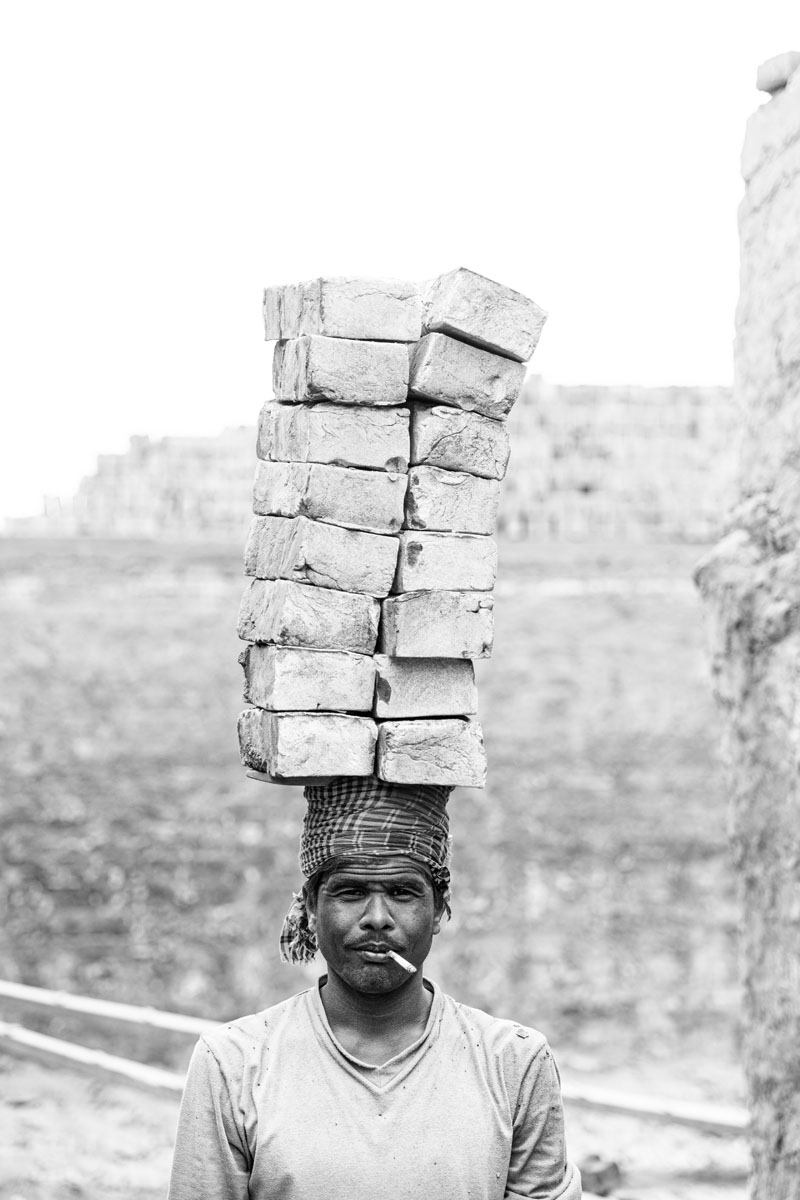

The bricks are made almost fully by hand, using a very old technology. The work is demanding – accidents occur often and the work is hard. Workers get paid for how many bricks they produce or can carry. For the fast workers, a week’s salary can range between 10 – 15 Euros a week. Nearly one million people work for 12-14 hours a day, almost every day of the week. Many of them live in the brick factories. Near almost every factory there are villages of the workers where all the families that work inside the factories are living.

Children form more than 10 percent of the total workforce. And they work as hard as the adults do.

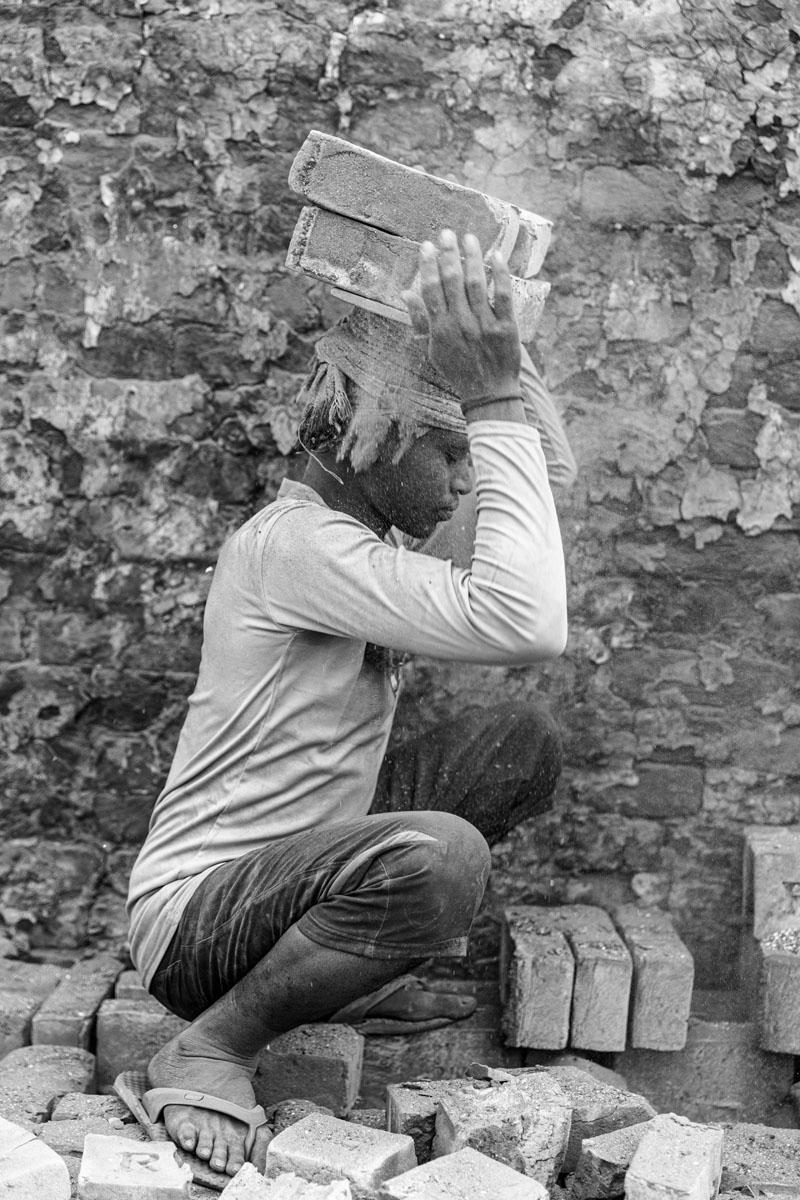

One brick weighs 2.5 kilograms. An adult carries about 10 to 16 bricks per run which is 25 to 40 kilograms. This is 2500 to 4000 kilograms if one runs a hundred times a day. One run could be 50-100 meters or more which is 10-20 km. And they work almost every day. What hard and physically demanding work this is!!

Workers, wearing only their normal clothes, are exposed to the red dust, which causes bronchitis and irritates the eyes and throat. The bricks are made almost entirely by hand, using a 150-year-old technology. The work is hard – accidents are common and the labor is tough. Workers earn according to how many bricks they produce or carry. For someone who works fast, a week’s salary may be around 1500 taka ($20). Nearly one million people work for 12-14 hours a day, six days a week. Many of them are trapped in the brick factories. Near almost every factory there are villages of the workers where all the families that work inside the factories are living. The houses are small and tiny, most only 1.5 meters high, so you can’t even stand up inside. As many as 10 people, often from three generations, would be living in a house measuring only a few square meters as shown in the pictures.

Every time a worker takes bricks from a pile to the kiln, they take a small token from the man shown seated. At the end of the week, the tokens are counted and their salary is paid accordingly. The job takes a toll on their bodies. They often experience pain in their legs, back, and shoulders. Many women get reproductive problems in the future after squatting for long hours when molding the bricks.

Men, women and children of all ages can be seen working at the factory.